The Corona surface treatment is essential in label printing. When the label is made from plastic substrate the ink tends to become blemished due to its inability to bond to the plastic. This problem occurs because the surface energy of the plastic is insufficient to permit a proper bond. A quality Corona treatment is necessary to ensure the perfect label print quality we all want to see when looking at products at the end of the production line. Therefore our Corona systems are not only designed for our customers in narrow web printing, but also for our customers’ customers, as our Corona systems help you obtain a flawless and long lasting quality print.

Often, our customers discover that batches of incoming material have low dyne level(surface adhesion) or that the dyne level of the material on stock has decreased due to heat or humidity. Due to the low dyne level the narrow printing press cannot run at full speed.As a consequence the Electro Tech Inc. Corona systems are used for boosting already treated materials to create high adhesion ability.

A common problem in the narrow web industry is the necessity for using top coated materials which have been chemically altered in order to obtain a high surface adhesion for inks. The top coated materials are more expensive to purchase than regular materials. By adding a Electro Tech Inc. Corona treater to your narrow web press, you will often eliminate the need for using top-coated materials and thereby decrease production costs significantly.

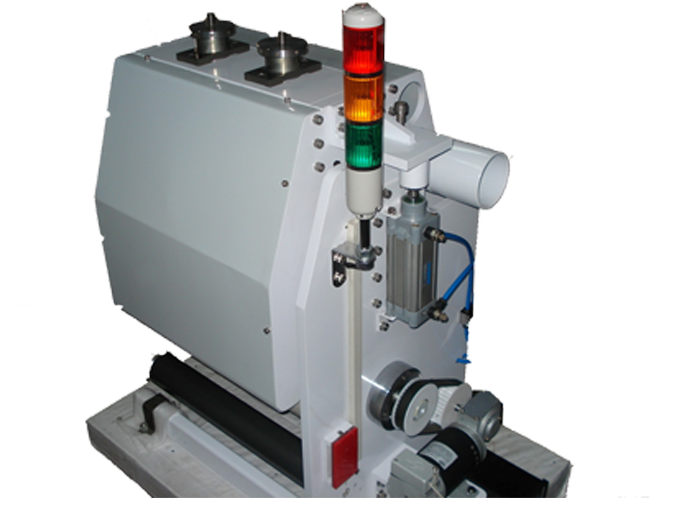

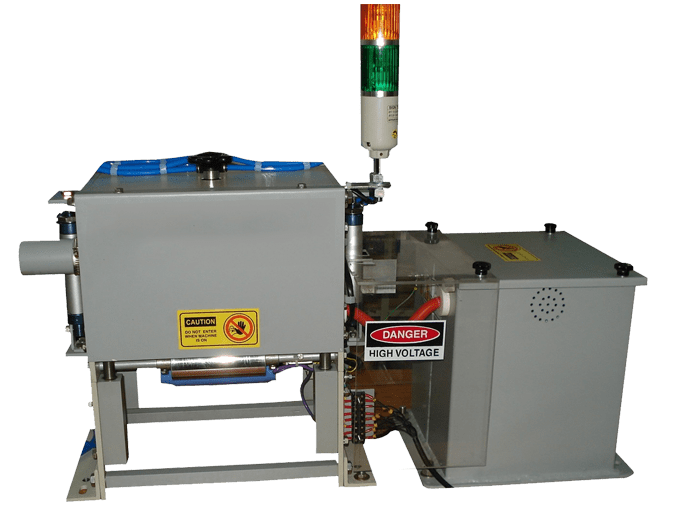

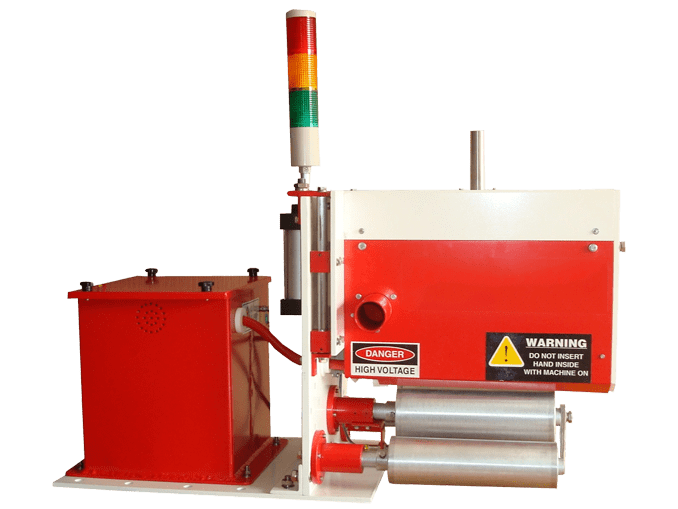

The new generation label press demands compact and efficient corona treatment systems for treatment of variety of substrates at high line speeds. Electro Tech Inc. Narrow Web Push-Pull type Corona Treating Station is specially designed keeping the compactness, operator friendliness and efficiency in mind.

Specifications

- Width : 200mm-500mm

- Speed : 1- 250 mtr./min

- Electrodes : Aluminum / Stainless Steel/ Ceramic Tubes

- Electrode Type: Segmented / Tubes / Strip / Multifins Extrusion Profile Type.

- No of Sides for Treatment : 1 ( 2-optional)

- Roll covering : Silicone Sleeve / Bare Roller

- Roller Dia : 75-150mm

- Application : Label Press

Optional Features

- Ceramic-coated Treater Rollers for longer operational life.

- Single side dual pass system.

Salient Features

- Working width up to 500mm.

- Working speeds up to 250 mpm.

- Up to 8 ceramic electrodes per side.for metalaside film

- Compact design to fit in smallest working spaces

- Proximity switch for zero speed sensing, pulse block and closed loop feedback for auto-watt density control.

- Specially designed assembly switch which ensure ultra-fast supply disconnection when actuated.

- Corrosion resistant paint.

- Easy pull out cartridge design for easy change of electrodes and its maintenance.

- Single or double side treatment.