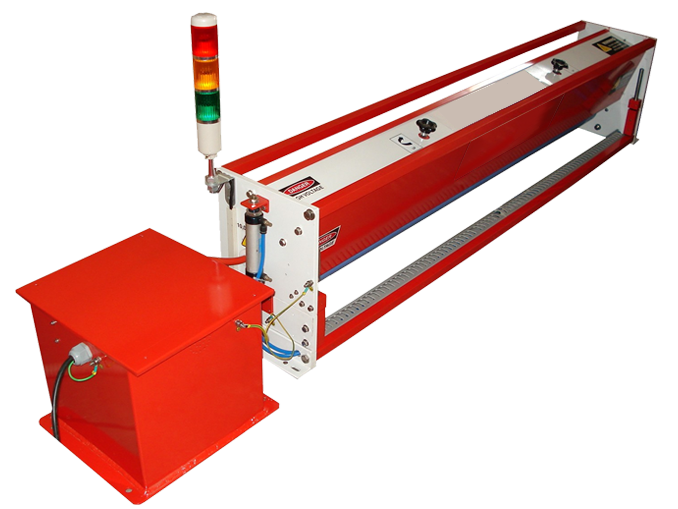

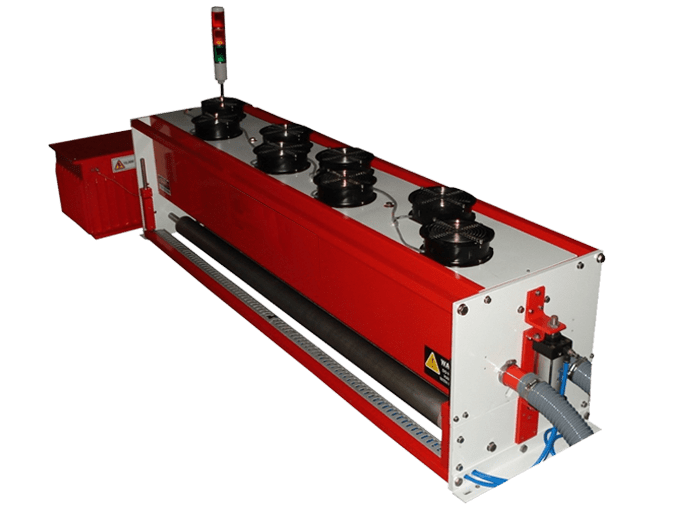

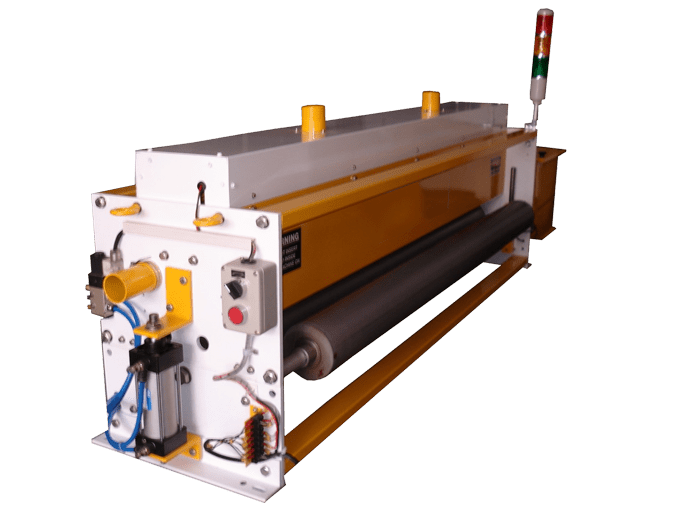

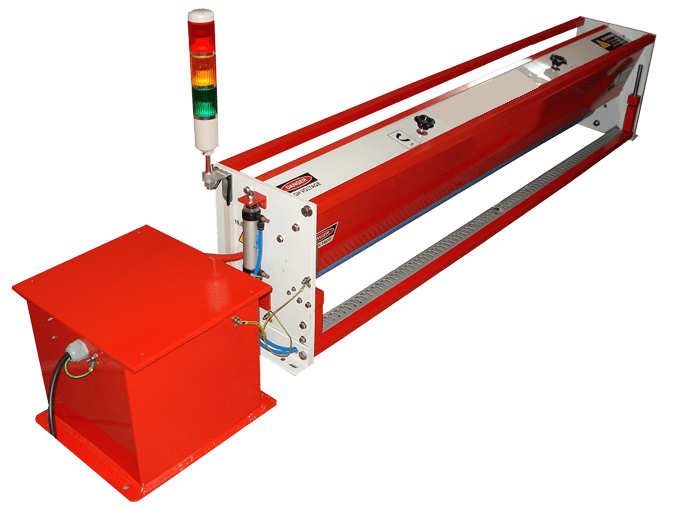

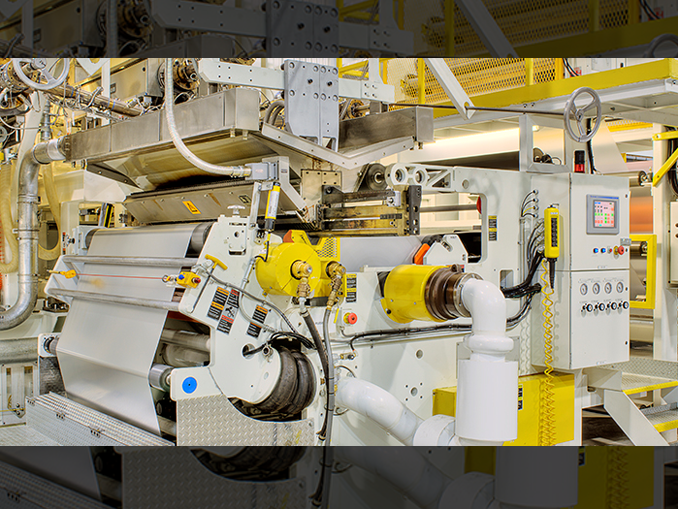

Converting applications such as Rotogravure /Flexographic printing solvent less/solvent based lamination, slitting, coating, Extrusion lamination /coating calls for treatment of verity of substrates at very high line speeds. Electro Tech Inc. Corona Treating Station comes with high definition ceramic electrodes which can treat metalized and non-metalized substrates at high line speeds.

The Corona surface treatment is essential in converting processes. A quality Corona is necessary to ensure that perfect laminating and printing result we all want to see when looking at products at the end of the production line. Therefore our Corona systems are not only designed for our converting customers, but also for our customers’ customers, as our Corona systems help you obtain a flawless and long lasting quality print and lamination.

Often our converting customers discover that batches of incoming material have low dyne level (surface adhesion) or that the dyne level of the material on stock has decreased due to heat or humidity. Due to the low dyne level the printing press or laminator cannot run at full speed.

In converting processes our Corona systems are used for boosting already treated materials to create high adhesion ability and a fresh clean surface that is receptive to ink, glue and lacquering.

Specifications

- Width : 800mm-4000mm

- Speed : 1- 600 mtr./min

- Electrodes : Aluminum / Stainless Steel/ Ceramic Tubes

- Electrode Type: Segmented / Tubes / Strip Type.

- No of Sides for Treatment : 1.2.4.

- Roll covering : Silicone Sleeve / Bare Roller

- Roller Dia : 50mm-200mm

- Types of Converting Lines : Roto/Flexo Printing / Lamination/ Coating / Extrusion Coating /Slitter

Optional Features

- Neoprene Coated Nip Roller and Motorized Driven Treater Roller.

- Ceramic Coated Treater Roller for longer roller life

- Air gap adjusters with digital readouts.

- Over pressurized treating station for explosion prone application

- Internal cooling of treatment roller for high demand applications.

Salient Features

- Corona Treater Rollers covered with high dielectric grade silicone sleeves.or Bare Anodised Roller for Ceramic Type Electrode.

- Pneumatically actuated treating heads / Split Assembly for easy threading of the films.

- 1dler rollers at film entry & exit to ensure proper wrap angle of film with treater roller

- Easy Inline air gap adjustment with knobs provided externally on the ducts.

- S.S. Braided double dielectric sheathed high tension cable to ensure safety

- Dynamically and statically balanced rollers

- Proximity switch for zero speed sensing & closed loop feedback for Auto watt density control

- Assembly open safety switch for human safety

- Rigid cross members and electrode holding bars to ensure uniform and parallel air gaps.

- Auto Spark off /on feature when roller stops /starts moving to prevent frequent stopping of Generator panel and to increase the production in converting lines where frequent start/stop occurs on converting machine.

- Auto open of treater assembly when roller stops moving to prevent any damage to expensive ceramic tubes due to high web tension jerk on electrode assembly